Steel Coil

China Steel Coil Manufacturer and Supplier

The Steel Coils we supply are including Galvanized Steel Coil, Galvalume Steel Coil, and Prepainted Galvanized Steel.

Galvanized Steel Coil

● Galvanized steel coils are steel coils that have been coated with a layer of zinc to protect against corrosion.

● They offer several benefits including corrosion resistance, durability, low maintenance, aesthetic appeal, recyclability and versatility.

Galvalume Steel Coil:

● Galvalume steel coil is a type of steel coil that is coated with a layer of aluminum-zinc alloy.

● Galvalume steel coils are commonly used in the construction industry for roofing and wall cladding, as well as in the automotive and appliance industries.

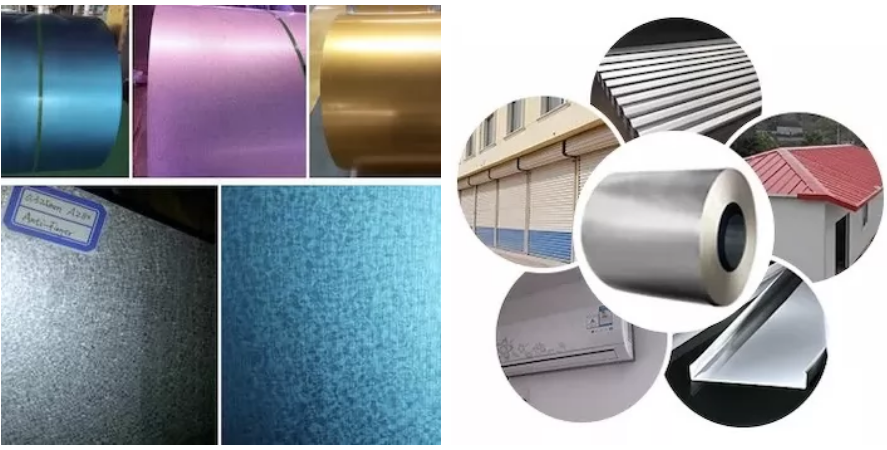

Prepainted Galvanized Steel:

● Prepainted galvanized steel is a type of steel that has been coated with a layer of paint before it is shipped to the customer.

● Prepainted galvanized steel is used in a variety of applications, including construction, automotive, and appliance manufacturing. The paint coating provides added protection against corrosion and weathering and also improves the aesthetic appeal of the steel.

● There are several benefits to using prepainted galvanized steel, including improved corrosion resistance, enhanced aesthetic appeal, reduced maintenance, and increased efficiency.

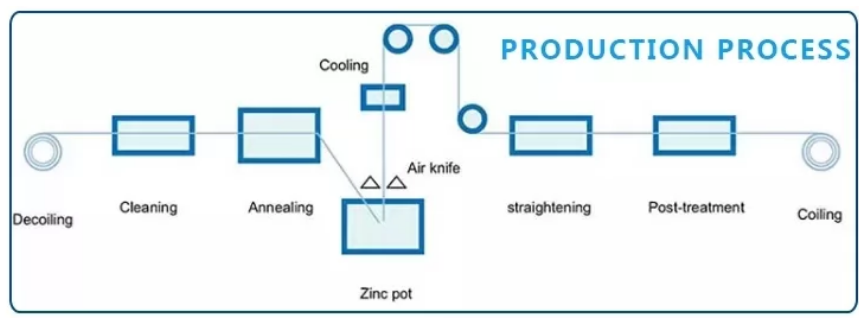

Steel Coil Production

1. Raw material preparation:

The first step in the production of steel coils is the preparation of the raw materials. This typically involves melting and refining steel scrap or iron ore in a furnace to produce molten steel.

2. Casting:

The molten steel is then poured into a casting machine, which shapes it into a continuous strip or sheet.

3. Hot rolling:

The steel strip or sheet is then passed through a series of rollers, which apply pressure to the steel and reduce its thickness. This process is known as hot rolling.

4. Cold rolling:

After hot rolling, the steel is cooled to room temperature and passed through a series of rollers to further reduce its thickness. This process is known as cold rolling.

5. Annealing:

The steel may be annealed after cold rolling to improve its ductility and formability. This is done by heating the steel to a high temperature and then cooling it slowly.

6. Finishing:

The steel may be finished with various coatings, such as zinc (for galvanized steel coils) or paint (for prepainted steel coils), to provide additional protection and improve its aesthetic appeal.

7. Slitting:

The steel coils may be slit into narrower widths to meet specific customer requirements.

8. Packaging:

The steel coils are then packaged and shipped to the customer.

Some Hot Sale Products You May be Interested

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error